Laser cleaning delivers non-contact, non-abrasive, precise removal of rust, coatings and contaminants without damaging the base material. At Reliant Rubber Engineers, this advanced capability replaces traditional shot blasting with a cleaner, safer and tightly controlled process delivered by engineers for performance-critical industrial applications supporting refurbishment, bonding and maintenance workflows across Yorkshire and the UK.

What is laser cleaning best at?

- Rust / oxide removal

- Paint / grease / coating removal

- Pre-bond / pre-coat / pre-weld surface prep

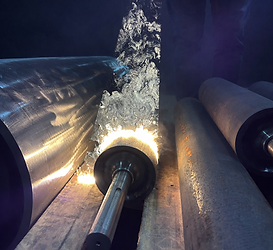

- Tooling / rollers / restoration

Laser cleaning video examples

Rust / oxide removal

Grease / oil removal

Standalone Laser Cleaning

We offer laser cleaning as a standalone service for customers who need precise, non-abrasive removal of rust, coatings, grease and surface contamination.

Where required this process integrates into our wider engineering activities such as refurbishment, bonding preparation and component repair.

From one-off components to ongoing maintenance support, the service is flexible to your needs.

Get in touch to discuss your application.

How Laser Cleaning Works

1. Controlled Laser Application

A precisely focused laser beam is applied to the contaminated surface.

2. Selective Energy Absorption

Contaminants absorb laser energy at a different rate to the base material.

3. Contaminant Removal Without Heat Damage

Rust, coatings, and residues are vaporised or lifted away with minimal thermal transfer.

4. Precision Control by Engineers

Pulse frequency, intensity, and pattern are adjusted to suit material type, thickness, and surface condition protecting even thin-gauge or precision-machined components.

This makes laser cleaning suitable for both heavy industrial restoration and delicate, high-value assets.

-

Industries We Support With Laser Cleaning

Automotive & Mechanical

Pre-bonding, pre-coating and controlled oxide or paint removal.

Production & Manufacturing

Tooling, jigs and production assets.

Print, Packaging & Processing

Rollers, drums and process equipment.

Hygiene Environments

Chemical-free contamination removal for hygiene-sensitive equipment.

Heritage & Restoration

Cleaning for historic and sensitive surfaces, preserving original material

_edited_.jpg)